About Aluminum Nanoparticles Nano Al Powder:In recent years, as potential applications in many fields have become more and more obvious, nano-aluminum powder has attracted extensive research […]

Continue readingAluminum Nanoparticles Nano Al Powder CAS 7429-90-5

About Aluminum Nanoparticles Nano Al Powder:

In recent years, as potential applications in many fields have become more and more obvious, nano-aluminum powder has attracted extensive research interest. Nano aluminum powder particles appear in the form of spherical gray or black particles and are aggregated together in the form of gray or black powder, and the size is usually 10nm to 5um.

Aluminum nano-powder improves the sintering process of ceramics, has higher heat transfer performance, higher density, and improves the thermal conductivity of the sintered body, and has good sintering ability and sunlight.

Aluminum nanopowders add aluminum (AI) to lead selenide (PbSe), and in the past few decades, the n-type PbSe thermoelectric material thermoelectric (TE) materials and devices produced have attracted people’s attention because they The combination of solar energy and waste to convert heat into electricity has potential application value. The performance of thermoelectric materials depends on electrical conductivity, absolute temperature, lattice thermal conductivity and electronic thermal conductivity.

Aluminum nano-powder can be used as an environmentally friendly generator, a highly reliable and accurate temperature controllable refrigerator electronic device. Because it is one of the simplest energy conversion technologies, it can be used for electrical energy conversion. Widespread concern. The thermoelectric efficiency depends on the basic characteristics of thermoelectric materials and the quality factor of thermoelectric materials. For centuries, because the thermoelectric effect can realize the direct conversion between thermal energy and electrical energy, thermoelectric materials have attracted widespread attention, thereby providing another method of power generation and cooling.

The Seebeck coefficient of aluminum nanopowder is a parameter that measures the efficiency of a material to generate a voltage from a specific temperature gradient. The effect of aluminum nanoparticles on the Seebeck coefficient of silicon-based thermoelectric generators was studied. This application is partly due to the inability to obtain effective thermoelectric materials and partly due to the high power required by biomedical equipment. Feel free to send an inquiry to get the latest price if you would like to buy Aluminum Nanoparticles Nano Al Powder in bulk.

Product Performance of Aluminum Nanoparticles Nano Al Powder:

Aluminum nanoparticles are light, have high floating power, strong hiding power, and has good light and heat reflection properties. Aluminum powder is a large class of metallic pigments due to its wide use, large demand and many varieties.

Technical Parameter of Aluminum Nanoparticles Nano Al Powder:

| Product Name | MF | Purity | Particle Size | CAS | Melting Point | Color |

| Aluminum Nanoparticles | Al | 99% | 50-70nm, 150nm | 7429-90-5 | 660℃ | Gray |

How is Aluminum Nanoparticles Nano Al Powder produced?

Nano aluminum powder is a product produced by the arc method and the electric explosion method. Compared with ultra-fine or larger particles of the same material, aluminum nanopowders have an enhanced size dependence. Aluminum nanoparticles are used as ingredients in solid rocket propellant formulations and explosives. Aluminum nanoparticles are produced through various physical and chemical methods. Line explosion, laser ablation, combustion flame and aerosol synthesis, but micro EDM system has not been studied to generate aluminum nanoparticles.

Application of Aluminum Nanoparticles Nano Al Powder:

1. Efficient catalyst: Nano aluminum powder is added to the solid fuel of the rocket, which greatly increases the fuel combustion speed and improves the combustion stability;

2. Activated sintering additives: 5-10% nano aluminum powder is mixed into AlN powder to reduce the sintering temperature and increase the density and thermal conductivity of the sintered body; if nano aluminum is used as the substrate for integrated components, the thermal conductivity will increase by about 10 times. Can solve the integration problem of integrated components.

3. Surface conductive coating treatment of metal and scrap metal: Due to the high activation surface energy of nano-aluminum, the coating can be applied at a temperature lower than the melting point of the powder under oxygen-free conditions. This technology can be applied to the production of microelectronic devices.

4. Widely used in high-grade metal pigments, composite materials (thermal spraying composite metal powder, ceramic composite steel pipe) military industry (filler), chemical industry (various chemical catalysts, pesticides), metallurgy (thermite metallurgy, steelmaking deoxidizer), Shipbuilding (conductive coatings), refractory materials (magnesia carbon bricks for steelmaking furnaces), new building materials (aerated concrete gas generators), anticorrosive materials, etc.

Storage Condition of Aluminum Nanoparticles Nano Al Powder:

The damp reunion will affect aluminum nanoparticles’ dispersion performance and using effects, therefore, nano Al powder should be sealed in vacuum packing and stored in cool and dry room, the nickel nanoparticles can not be exposure to air. In addition, the Al Nanoparticles should be avoided under stress.

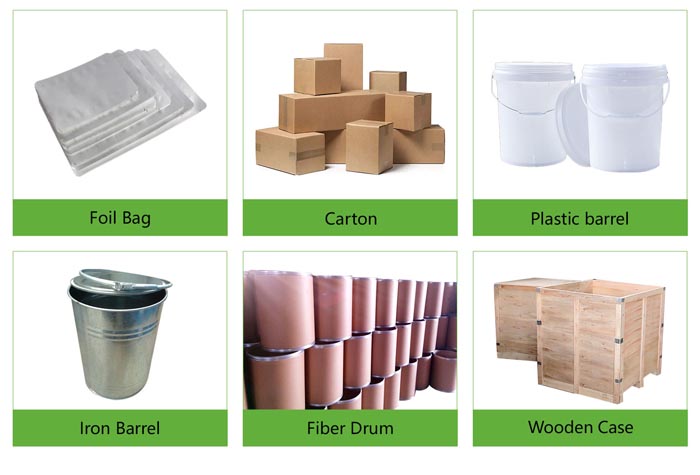

Packing & Shipping of Aluminum Nanoparticles Nano Al Powder:

We have many different kinds of packing which depend on the aluminum nanoparticles’ quantity.

Aluminum nanoparticles packing: vacuum packing, 1kg/bag, 25kg/barrel, or as your request.

Aluminum nanoparticles shipping: could be shipped out by sea, by air, by express as soon as possible once payment receipt.

Aluminum Nanoparticles Properties | |

| Other Names | Aluminium nanopowder, nanoaluminum, Al nanoparticles, Nano Al Powder |

| CAS No. | 7429-90-5 |

| Compound Formula | Al |

| Molecular Weight | 26.98 |

| Appearance | Gray to Black Powder |

| Melting Point | 660 ℃ |

| Boiling Point | 2467 ℃ |

| Specific Surface Area | 40-60 m2/g |

| Solubility in H2O | N/A |

| Thermal Expansion | (25 °C) 23.1 µm·m-1·K-1 |

Aluminum Nanoparticles Health & Safety Information | |

| Signal Word | Danger |

| Hazard Statements | H228 |

| Hazard Codes | F |

| Risk Codes | N/A |

| Safety Statements | N/A |

| Transport Information | UN1309 – class 4.1 – PG 2 |