What is Titanium Nitride? Titanium Nitride, also known as TiN in chemical form, is a synthetic ceramic that’s almost as hard than diamond. To improve […]

Continue readingPromising Titanium Nitride

What is Titanium Nitride? Titanium Nitride, also known as TiN in chemical form, is a synthetic ceramic that’s almost as hard than diamond. To improve the surface properties of aluminum structures, titanium alloys as well as steel and hard alloys are commonly coated with it. The thin layer of titanium nitride serves as a protective coating that hardens and protects cutting and sliding surfaces.Properties for Titanium Nitride

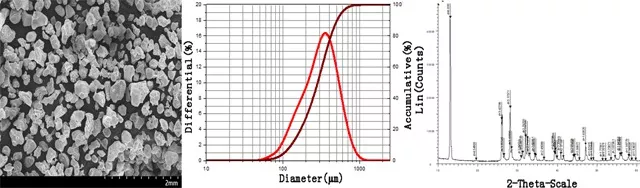

At room temperature, titanium nitrous dioxide is stable chemically. However, hot concentrated acid can cause it to be destroyed and then oxidized at 800. This oxide has an infrared reflection characteristic, which makes it yellowish. The relative friction coefficient of titanium Nitride varies according to the finish of various substrate materials.Application to Titanium Nitride

A titanium nitride coat is commonly used on metal edges in order to preserve the mechanical corrosion resistance. Because of its metallic luster it is often used as clothing or car decoration in the outer coating. The coating can also be used in military and aerospace aspects as well as protection for bicycle suspension surfaces and remote-controlled toy cars suspension shafts. The FDA approved material is safe and non-toxic. It can be used for medical purposes, including maintaining the sharp edges of orthopedic bone saws and scalpel blades. Tungstenmolybdenummetals (aka. Tungstenmolybdenummetals is an advanced material. With over 12 years’ experience, Tungstenmolybdenummetals is an established global supplier of chemical material. High purity, small particles size and low impurities are the hallmarks of the Titanium Nitride that our company produces. We can help you if your requirements are lower.Inquiry us