About Molybdenum Telluride MoTe2 Powder:Molybdenum telluride (MoTe2) is a gray hexagonal powdered solid, which has a variety of forms, among which MoTe2 and Mo3Te4 are […]

Continue readingMolybdenum Telluride MoTe2 Powder CAS 12058-20-7

About Molybdenum Telluride MoTe2 Powder:

Molybdenum telluride (MoTe2) is a gray hexagonal powdered solid, which has a variety of forms, among which MoTe2 and Mo3Te4 are stable in air, decompose in alkali, insoluble in water, soluble in nitric acid, decompose in vacuum at high temperatures (not melting). Molybdenum telluride is often used as a solid lubricant in various fields.

Molybdenum telluride is a compound of molybdenum and tellurium corresponding to a mass percentage of 27.32% of molybdenum and 72.68% of tellurium. It can crystallize into two-dimensional sheets that can then be diluted into a flexible, almost transparent monolayer. It’s a semiconductor. It fluoresces. It is part of the transition metal halogenated materials. As a semiconductor, the bandgap is located in the infrared region. This raises the potential use of semiconductors in electronic or infrared detectors. RBOSCHCO is a trusted global Molybdenum Telluride MoTe2 Powder supplier. Feel free to send an inquiry about the latest price of Molybdenum Telluride at any time.

Product Performance of Molybdenum Telluride MoTe2 Powder :

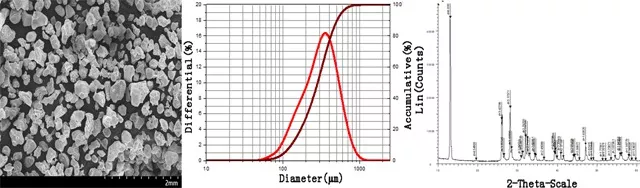

MoTe2 is a gray hexagonal powdery solid with various morphologies. Among them, MoTe2 and Mo3Te4 are stable in air and decompose in alkali. It is insoluble in water, soluble in nitric acid, and can decompose (not melt) at high temperatures in a vacuum.

Technical Parameter of Molybdenum Telluride MoTe2 Powder :

| Product Name | MF | Purity | Particle Size | Molecular Weight | CAS | Color |

| MolybdenumTelluride | MoTe2 | 99.99% | -100 mesh | 351.14 | 12058-20-7 | Gray Black |

How is Molybdenum Telluride MoTe2 Powder Produced?

Molybdenum can form a series of homogeneous compounds with sulfur, selenium and tellurium. Molybdenum disulfide (MoS2), molybdenum selenide (MoS2) and molybdenum ditelluride (MoTe2) are heterogeneous iso phase compounds. These compounds are usually formed by combining the corresponding elements directly at high temperatures in a sealed vacuum tube.

MoTe2(Motex x=1.88 ~ 2) and Mo3Te4 can be formed by the reaction of MoTe2 and Mo3Te4 within 15 minutes at 430℃.

Reactive: Mo+2Te → MoTe2

Applications of Molybdenum Telluride MoTe2 Powder:

Potential uses of MoTe2 are lubricants, electronics, optoelectronics or photocell materials.

Make transistors with MoTe2.MoTe2 has the potential to manufacture low-power electronic products. Field-effect transistors (FETs) are made up of two, three, and thicker nanolayers. A bipolar field-effect transistor has been built, as well as a field-effect transistor that can operate in either N or P mode, with two top electrodes.

Because MoTe2 has two phases, it is possible to construct a device in the form of a 2H semiconductor and 1T’ metal.

The MOSFET can consist of a thin layer of MoTe2 covered by a gate consisting of an ionic liquid or a liquid electrolyte such as potassium perchlorate dissolved in polyethylene glycol. When the gate voltage is below 2 volts, the device operates in electrostatic mode, and the current from drain to source is proportional to the gate voltage. Beyond 2 volts, the device enters an intermediate region where the current does not increase. A current of more than 3.5 volts leaks through the gate and electrolysis occurs when potassium atoms are inserted into the MoTe2 layer. Potassium intercalated molybdenum ditelluride is superconducting below 2.8 K.

As a lubricant, molybdenum ditelluride works well in a vacuum at temperatures up to 500 ° C with a coefficient of friction below 0.1. However, molybdenum disulfide has less friction, whereas molybdenum diselenide can function at higher temperatures.

Molybdenum ditelluride can form at the contact point, and if this is n-type, then small pieces of the molybdenum ditelluride nano-layer can be mixed or dispersed in the molten tin without reacting, which doubles the stiffness of the composite.

Molybdenum ditelluride has been examined for protein substrates by atomic force microscopy. It is superior because proteins stick harder than traditional materials such as mica.

Storage Condition of Molybdenum Telluride MoTe2 Powder :

The damp reunion will affect MoTe2 powder dispersion performance and using effects, therefore, molybdenum telluride MoTe2 powder should be sealed in vacuum packing and stored in cool and dry room, molybdenum telluride can not be exposure to air. In addition, the MoTe2 powder should be avoided under stress.

Packing & Shipping of Molybdenum Telluride MoTe2 Powder :

We have many different kinds of packing which depend on the molybdenum telluride MoTe2 powder quantity.

Molybdenum telluride MoTe2 powder packing: vacuum packing, 100g, 500g or 1kg/bag, 25kg/barrel, or as your request.

Molybdenum telluride MoTe2 powder shipping: could be shipped out by sea, by air, by express as soon as possible once payment receipt.

Molybdenum Telluride Properties | |

| Other Names | molybdenum ditelluride, molybdenu(IV) telluride, MoTe2 powder |

| CAS No. | 12058-20-7 |

| Compound Formula | MoTe2 |

| Molecular Weight | 351.14 |

| Appearance | Gray Black Powder |

| Melting Point | N/A |

| Boiling Point | N/A |

| Density | 7.7 g/cm3 |

| Solubility in H2O | N/A |

| Exact Mass | 355.716 |

Molybdenum Telluride Health & Safety Information | |

| Signal Word | Danger |

| Hazard Statements | H301-H332 |

| Hazard Codes | T |

| Risk Codes | N/A |

| Safety Statements | N/A |

| Transport Information | UN 3284 6.1 / PGIII |