About Tungsten Boride WB2:Tungsten borides are compounds of tungsten and boron. Their most remarkable property is high hardness. The Vickers hardness of WB or WB2 crystals […]

Continue readingTungsten Boride WB2 Powder CAS 12007-09-9

About Tungsten Boride WB2:

Tungsten borides are compounds of tungsten and boron. Their most remarkable property is high hardness. The Vickers hardness of WB or WB2 crystals is ~20 GPa and that of WB4 is ~30 GPa for loads exceeding 3N.

The relative density of tungsten boride is 10.77 and the melting point is about 2900°C. It does not degrade water and can degrade aqua regia.

It is prepared by heating boron and tungsten powder to a high temperature.

Tungsten boride has comprehensive properties such as high melting point, high hardness and chemical stability. It is only a new superhard material with a high melting point. It is an important military bulletproof material.

For more than 50 years, it has been considered that the rich phase diagram of tungsten alloys, the structure of different phases is also ever-changing.

The highest boride is WB4, which has a three-dimensional grid structure of boron atoms. We put the first the principle calculation is combined with the thermodynamic stability, and the thermodynamic stability and mechanical properties of the possible structure of the tungsten carbide system are systematically studied:

The highest boride to identify tungsten should be WB3 composed of two-dimensional plane boron atoms, not WB4 composed of three-dimensional boron atom grids. It was found that the shear modulus in the borate system of tungsten transformed its formation energy. Increase, revealing that the mechanical properties are closely related to their thermodynamic stability.

Due to the free diffusion coefficient of WB2, the total synthesis of dense tungsten diboride is mostly achieved by sintering technology under high temperature and high-pressure conditions. In this way, it is reduced and the cost is too high; instead, because B will volatilize at high temperature.

Therefore, it is difficult to grasp the content of boron to prepare WB2 bulk materials directly from tungsten powder and boron powder.

It may also generate hypoborate during the sintering process, and compact bulk material with WB2 as the main phase cannot be obtained. Feel free to send an inquiry to get the latest price if you would like to buy Tungsten Boride WB2 powder in bulk.

How is Tungsten Boride WB2 produced?

1. Using metal tungsten and boron as raw materials, fully mix and grind the two, heat and react at above 1400 ℃ to obtain tungsten boride, continue to react to form W2B, and then cool and crush to obtain the product.

2. Tungsten is mixed with stoichiometric boron powder at a molar ratio of W: B=2:1 and sintered in a vacuum or argon atmosphere at 1200 to 1300°C to obtain two tungsten boride.

3. Use the solid phase method. Tungsten boride is prepared from metal tungsten and boron. The reaction formula is as follows. The stoichiometric metal tungsten powder and elemental boron are fully mixed, ground, and molded, and heated and reacted at a temperature above 1400°C to obtain tungsten boride. Continue the reaction to generate W2B, which is cooled and crushed to obtain the product.

Tungsten boride WB2 powder Feature

Tungsten boride powder Molecular formula: WB2

Tungsten boride powder CAS NO:12007-09-9

Tungsten boride powder density:10.77g/cm3

Tungsten boride powder melting point:2900℃

Tungsten boride powder Solubility and Stability

Does not dissolve in water. Dissolved in aqua regia and certain concentrated acid.100 ℃ can be chlorine gas decomposition

Tungsten boride powder Purity: >99%

Tungsten boride powder Particle size: 10-20um

Applications of Tungsten Boride WB2:

Wear-resistant coating for wear parts and semiconductor thin film.

WB series compounds have a high melting point, high hardness, high conductivity, wear resistance, high-temperature resistance and corrosion resistance. They also have comprehensive neutron and gamma-ray shielding properties, so they are widely used in structural materials, wear-resistant materials, and electrodes. Materials and other fields. Tungsten boride is obtained by the direct reaction of metal tungsten and element boron heated by an electric furnace. It has the excellent properties of W-B series compounds and has broad application prospects in the future.

1) Prepare a workpiece with a tungsten boride-rich coating, including a workpiece substrate, and a tungsten layer, a tungsten boride gradient layer, and a tungsten boride coating that are sequentially arranged on the workpiece substrate; In the direction of the thickness of the tungsten layer, the boron content in the tungsten boride gradient layer gradually increases; the unique coating structure can make the bonding strength between the layers high, and the elastic modulus and thermal expansion between the layers The coefficient changes gradually from the substrate to the top film, reducing the overall coating stress to zero and improving the toughness and bonding force of the boride-rich tungsten coating.

2) To prepare a hard material of tungsten diboride, the method first uses a mechanochemical method to synthesize tungsten diboride powder at room temperature with high-purity tungsten (W) powder and boron (B) powder as raw materials, and then in argon Under a protective atmosphere, high-temperature sintering is used to densify the synthesized powder to produce a bulk material of tungsten diboride. This method can obtain compact tungsten diboride bulk material through sintering under normal temperature and pressure conditions. The prepared tungsten diboride bulk material has a series of excellent properties such as certain hardness, good stability and good neutron absorption effect. It has a wide range of applications in corrosion-resistant materials, cutting tools, and new shielding materials.

Storage Condition of Tungsten boride WB2 powder:

The damp reunion will affect WB2 powder dispersion performance and using effects, therefore, tungsten boride WB2 powder should be sealed in vacuum packing and stored in cool and dry room, the tungsten boride WB2 powder can not be exposure to air. In addition, the WB2 powder should be avoided under stress.

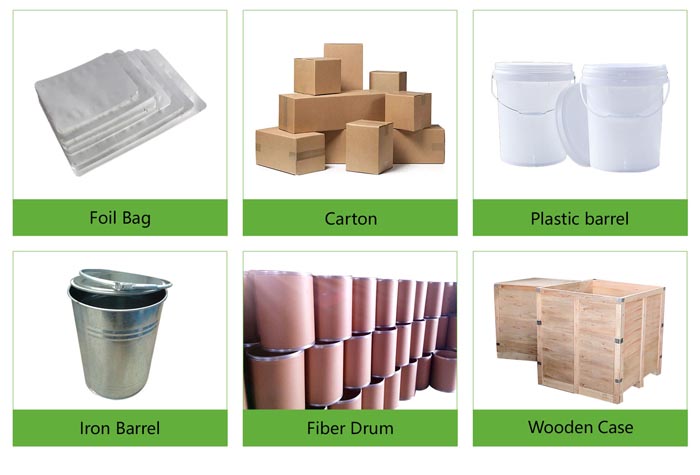

Packing & Shipping of tungsten boride WB2 powder:

We have many different kinds of packing which depend on the tungsten boride WB2 powder quantity.

Tungsten boride WB2 powder packing:vacuum packing, 100g, 500g or 1kg/bag, 25kg/barrel, or as your request.

Tungsten boride WB2 powder shipping: could be shipped out by sea, by air, by express, as soon as possible once payment receipt.

Tungsten Diboride Properties | |

| Other Names | tungsten boride, WB2 powder, tungsten boride WB2 |

| CAS No. | 12007-09-9 |

| Compound Formula | WB2 |

| Molecular Weight | 205.5 |

| Appearance | Gray Black Powder |

| Melting Point | 2365 °C |

| Boiling Point | N/A |

| Density | N/A |

| Solubility in H2O | N/A |

| Vickers Hardness | 20 GPa |

| Exact Mass | 205.969544 g/mol |

| Tungsten Diboride Health & Safety Information | |

| Signal Word | N/A |

| Hazard Statements | N/A |

| Hazard Codes | N/A |

| Risk Codes | N/A |

| Safety Statements | N/A |

| Transport Information | N/A |